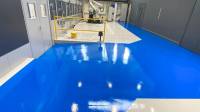

At Industrial Resin Flooring, we take pride in delivering high-quality resin flooring solutions across the UK. With over 25 years of experience, we specialise in epoxy flooring and industrial resin flooring thats built to last. From manufacturing plants to warehouses and aerospace facilities, weve worked across a wide range of industries that demand performance, durability, and safety.

At Industrial Resin Flooring, we take pride in delivering high-quality resin flooring solutions across the UK. With over 25 years of experience, we specialise in epoxy flooring and industrial resin flooring thats built to last. From manufacturing plants to warehouses and aerospace facilities, weve worked across a wide range of industries that demand performance, durability, and safety.We handle everything from expert surface preparation to flawless installation, using only top-grade materials that meet industry standards. Our epoxy flooring systems offer excellent resistance to chemicals, heavy traffic, and impactmaking them ideal for demanding environments.

We understand that every project is unique, which is why we offer tailored flooring solutions to meet specific operational needs. Whether its a clean, slip-resistant finish for a warehouse or a heavy-duty surface for aerospace operations, were here to deliver.

As proud members of the Resin Flooring Association (FeRFA), we remain committed to quality, innovation, and customer satisfaction. We also offer competitive pricing without compromising on standards, ensuring long-lasting value with every installation.

If youre looking for trusted, professional resin flooring with a personal touch and proven resultsget in touch with us. Were here to help bring your floors up to industry standard.

Served areas

- Bedfordshire, Berkshire, Bristol, Buckinghamshire, Cambridgeshire, Cheshire, City of London, Cornwall, Cumbria, Derbyshire, Devon, Dorset, County Durham, East Riding of Yorkshire, East Sussex, Essex, Gloucestershire, Greater London, Greater Manchester, Hampshire, Herefordshire, Hertfordshire, Isle of Wight, Kent, Lancashire, Leicestershire, Lincolnshire, Merseyside, Norfolk, North Yorkshire, Northamptonshire, Northumberland, Nottinghamshire, Oxfordshire, Rutland, Shropshire, Somerset, South Yorkshire, Staffordshire, Suffolk, Surrey, Tyne and Wear, Warwickshire, West Midlands, West Sussex, West Yorkshire, Wiltshire, Worcestershire

Business details

- Year established: 2013

- Licensed

- Insured

Highlights and features

- Free Quotation

- Free Site Visit

- 25 years of expertise in resin flooring

Associations and certifications

- FERFA Accredited Contractor

- Enviornment Agency Authorised Waste Carrier

- SAFE Contractor Approved

- Flooring Industry Awards Finalist

Payment methods

- Cash, Debit cards, Credit cards, Bank transfers

Follow us

Services

Key Features of Epoxy Resin Flooring

Key Features of Epoxy Resin FlooringChemical Resistance: Ideal for areas exposed to aggressive chemicals, oils, and cleaning agents.

Durability: High compressive strength and abrasion resistance for heavy-duty use.

Seamless Finish: Smooth, joint-free surface for easy cleaning and hygiene control.

Customisable: Available in various colours, textures, and decorative options.

Anti-Static and ESD Options: Suitable for electronics and sensitive environments.

Slip Resistance: Configurable surface profiles for improved underfoot safety.

Fast Cure Times: Reduced downtime and quicker return to service.

Epoxy high build coating refers to a thick-layered resin flooring system made from 100% solids epoxy. Applied at a typical thickness of 300500 microns per coat, this system creates a seamless, durable surface that bonds directly to the concrete substrate.

Epoxy high build coating refers to a thick-layered resin flooring system made from 100% solids epoxy. Applied at a typical thickness of 300500 microns per coat, this system creates a seamless, durable surface that bonds directly to the concrete substrate.Unlike standard epoxy paints or sealers, high build epoxy is engineered to withstand the rigours of industrial operations. It acts as a dust sealer, protecting production areas from airborne concrete particles, a critical requirement in precision manufacturing environments where contamination could compromise sensitive components such as engines or electronics.

This type of epoxy flooring also provides a defensive barrier against oil ingress and minor chemical exposure. Once oils penetrate uncoated concrete, the floor becomes increasingly difficult to clean, maintain, or overcoat. A high build epoxy coating helps prevent this by sealing the concrete surface from day one.

What is Self-Levelling Epoxy?

What is Self-Levelling Epoxy?A self-levelling epoxy floor coating is a liquid-applied resin system that naturally levels itself to form an ultra-smooth, seamless surface once poured. Applied at a typical thickness of 2 to 4 mm, self-levelling epoxy resin creates a hard-wearing, glossy finish ideal for areas that demand hygiene, easy cleaning, and visual inspection.

Unlike high-build epoxy, which is roller-applied, or epoxy screeds, which are thicker and more labour-intensive, self-levelling concrete epoxy flows into place, eliminating irregularities in the substrate and curing into a uniform, flat finish. Its especially popular in pharmaceutical cleanrooms and other contamination-sensitive industries, where the ability to visibly detect dirt or spills is essential.

An anti-static epoxy floor, also referred to as anti-static epoxy flooring or ESD epoxy floor, is a specialist resin floor system designed to safely dissipate static electricity. These epoxy floors are critical in environments where a static charge could result in damage to sensitive electronics or create an explosion risk.

An anti-static epoxy floor, also referred to as anti-static epoxy flooring or ESD epoxy floor, is a specialist resin floor system designed to safely dissipate static electricity. These epoxy floors are critical in environments where a static charge could result in damage to sensitive electronics or create an explosion risk.Anti-static epoxy works by directing electrical charges away from the floor surface through an integrated network of conductive elements, including copper strips and earthing points, and safely grounding them. The result is a seamless, hard-wearing, and chemically resistant floor that actively prevents static build-up and discharge.

Epoxy mortar is a highly durable and chemically resistant industrial flooring system made from a blend of epoxy resin and graded aggregates. The result is a dense, trowel-applied mortar that provides outstanding mechanical strength and impact resistance.

Epoxy mortar is a highly durable and chemically resistant industrial flooring system made from a blend of epoxy resin and graded aggregates. The result is a dense, trowel-applied mortar that provides outstanding mechanical strength and impact resistance.Typically used to resurface damaged concrete or create a seamless, solid-colour finish in high-traffic industrial areas, epoxy resin mortar serves both as a repair solution and a standalone system. A high-build coating is usually applied over the top, enhancing performance and aesthetics. Epoxy mortar flooring is increasingly specified in UK manufacturing environments that demand long-term durability and easy maintenance.

Epoxy quartz screed flooring is a decorative variant of the standard epoxy mortar system. It incorporates a blend of coloured quartz aggregates within a robust epoxy resin binder, creating a seamless, attractive, and hard-wearing surface. Unlike conventional epoxy resin floors, decorative quartz screed offers a textured finish that not only enhances slip resistance but also delivers a visually appealing finish ideal for modern industrial and commercial environments.

Our resin kitchen flooring offers a sophisticated yet practical surface that resists spills, heat, and heavy foot traffic. Tailored to meet the demands of commercial and residential kitchens alike, it features a seamless, hygienic finish that is easy to maintain, ensuring your kitchen remains both safe and visually appealing over time.

Our resin kitchen flooring offers a sophisticated yet practical surface that resists spills, heat, and heavy foot traffic. Tailored to meet the demands of commercial and residential kitchens alike, it features a seamless, hygienic finish that is easy to maintain, ensuring your kitchen remains both safe and visually appealing over time.  Choosing Industrial Resin Flooring for your warehouse flooring needs guarantees a product that is durable, safe, and visually appealing. Our resin floors are engineered to resist wear and tear from heavy use and provide slip resistance for enhanced safety. We also offer tailored finishes to complement your workspace design.

Choosing Industrial Resin Flooring for your warehouse flooring needs guarantees a product that is durable, safe, and visually appealing. Our resin floors are engineered to resist wear and tear from heavy use and provide slip resistance for enhanced safety. We also offer tailored finishes to complement your workspace design.  Our industrial resin flooring solutions deliver exceptional durability and adaptability, making them ideal for environments with heavy machinery and frequent foot traffic. The slip-resistant surface enhances safety, while the design flexibility allows it to be tailored to specific industrial needs. Maintenance is minimal, contributing to reduced lifetime costs.

Our industrial resin flooring solutions deliver exceptional durability and adaptability, making them ideal for environments with heavy machinery and frequent foot traffic. The slip-resistant surface enhances safety, while the design flexibility allows it to be tailored to specific industrial needs. Maintenance is minimal, contributing to reduced lifetime costs.  Our resin flooring for indoor spaces offers a robust and adaptable solution that is suited to a variety of interior settings. It is carefully engineered by our team of experts, providing exceptional durability along with a non-slip finish. It comes in a range of colours and finishes, combining practical advantages with visual appeal, and is easy to maintain.

Our resin flooring for indoor spaces offers a robust and adaptable solution that is suited to a variety of interior settings. It is carefully engineered by our team of experts, providing exceptional durability along with a non-slip finish. It comes in a range of colours and finishes, combining practical advantages with visual appeal, and is easy to maintain.

Reviews (2)

Gary Hogan

May 06, 2025

Jamie Farrell

Feb 21, 2025

Our slip resistant flooring solutions are designed for industries that prioritise health and safety. They offer durable protection in spill-prone and high-traffic areas, combining superior resistance with straightforward upkeep to extend the floors lifespan.

Our slip resistant flooring solutions are designed for industries that prioritise health and safety. They offer durable protection in spill-prone and high-traffic areas, combining superior resistance with straightforward upkeep to extend the floors lifespan.  The outdoor resin flooring we offer guarantees resilience against tough environmental factors and heavy use. Tailored finishes and a durable construction provide both aesthetic flexibility and long-lasting performance, all at a competitive price point suited to diverse industrial needs.

The outdoor resin flooring we offer guarantees resilience against tough environmental factors and heavy use. Tailored finishes and a durable construction provide both aesthetic flexibility and long-lasting performance, all at a competitive price point suited to diverse industrial needs.